decarbonising the built environment.

Conventional construction may be the single guiltiest party when it comes to green wash.

There is much to be done to decarbonise our built environment, and it starts with measuring the carbon correctly.

Up until recently, the attention on efficiency was focused on operational carbon - how much energy/carbon a building consumes when in use. This is certainly important, but it is an incomplete measurement.

Enter the Whole Life Carbon metric (WLC) and Life Cycle Analysis (LCA). These measurements are holistic, they consider the provenance of the materials involved, their extraction, processing, manufacture, transportation, distribution, installation, performance, removal, and disposal. Their whole life. This is also known as cradle to grave. It’s the whole picture so it is detailed and nuanced, and it paints a stark picture once everything is added up, a picture that can reject certain materials regardless of how well they perform due to the considerable harm they cause at any other point in their life cycle.

This is relatively new, and the industry acceptance and understanding of the ramifications of this metric is lagging behind somewhat.

We Make Good is all about taking the vast breadth of knowledge from:

+ conservation and heritage processes and materials

+ conventional technologies

+ modern building science

+ emerging technologies, products, and materials

+ bio based materials (natural) building

We live at the intersection of all of these sectors. We take this knowledge, our experience, and that of our network of collaborators to design or retrofit truly sustainable structures. Ones that leave a light footprint, are high performance, healthy, and beautiful.

We lean heavily on our low carbon materials palette, materials that are derived from nature, have little processing, and have multiple functions.

Straw, timber, wool, earth.

As a species we have been building with some of these materials for millennia. When designed in tandem with cutting-edge materials science we can create buildings that are some of the most high performance buildings on the planet, without costing the earth.

The open house project is our flagship initiative for the built environment.

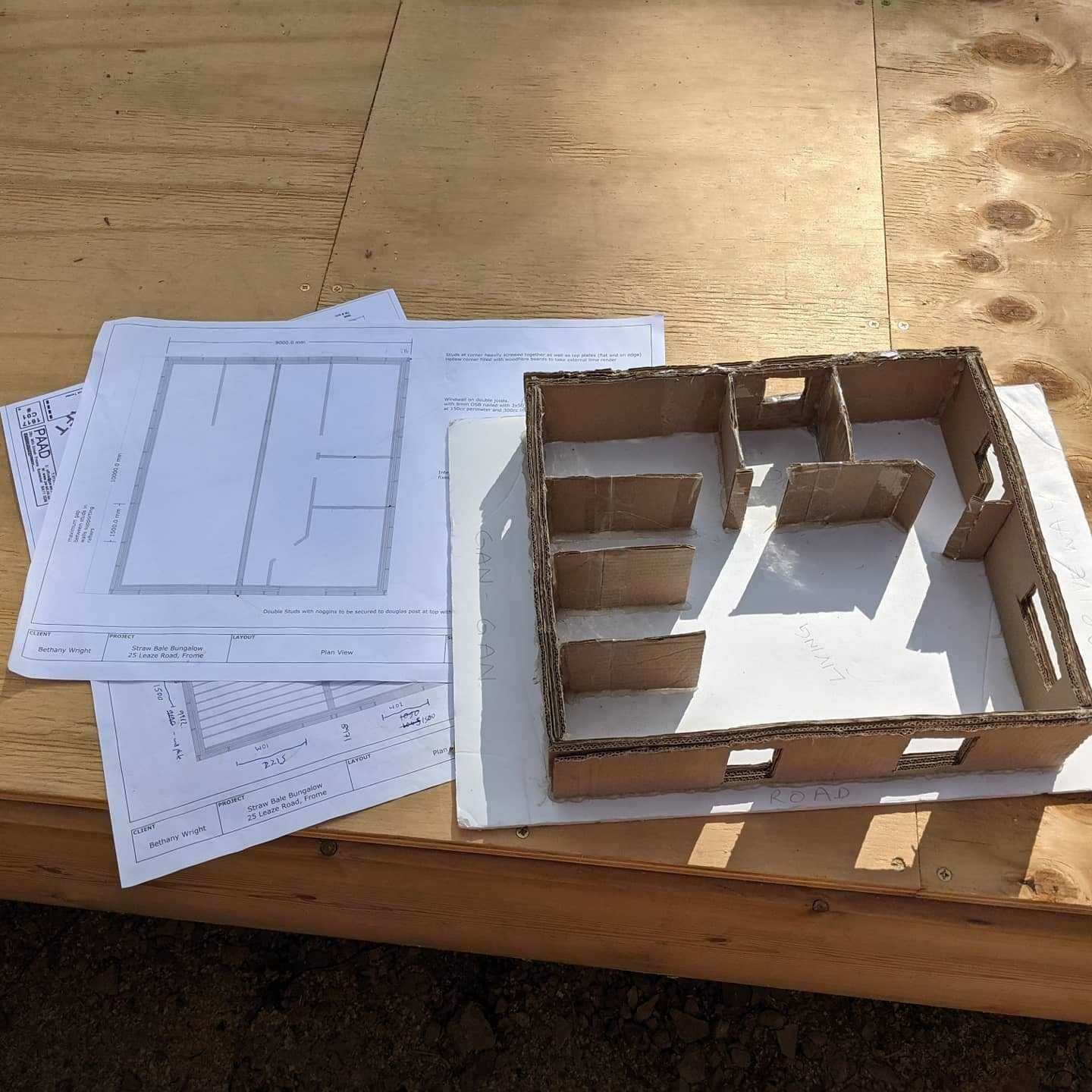

Inspired by cutting edge modular prefabricated housing solutions, stripping it back and creating a panel system for self building.

Simple, high performance, and buildable by two people in a barn with hand tools.

It uses a flexible palette of materials so that you can use the most local variant available, including minimally processed rough sawn timber and locally grown natural insulations.

Services

-

From project conception, right the way through the design process. With your architect or one of our network we can fully realise your dream and translate it into a practical, deliverable, efficient project.

-

Drawing on years of experience and a deep geeky love for emerging and traditional technologies, we can provide detailed project specific guidance on the best low carbon materials and build-ups.

-

Navigate these complex steps with the help of experience and a versatile network of collaborating professionals

-

Arguably the most important part of any project. We can shine a light on the intricacies of budgeting and cost planning, providing a detailed location specific financial overview.

-

Finding a competent and trustworthy contract team is incredibly important and fraught with worry. Contractors working with low carbon materials are few and far between. There are two options - Draw on the existing network or upskill the conventional contract workforce.

-

During the delivery phase of your project. Support to yourself or the contract team. Remote or onsite training, technical guidance, supplier liaison.

-

Practical workshops or classroom lectures. Professional development, academic, or trade.